What is Aeration?

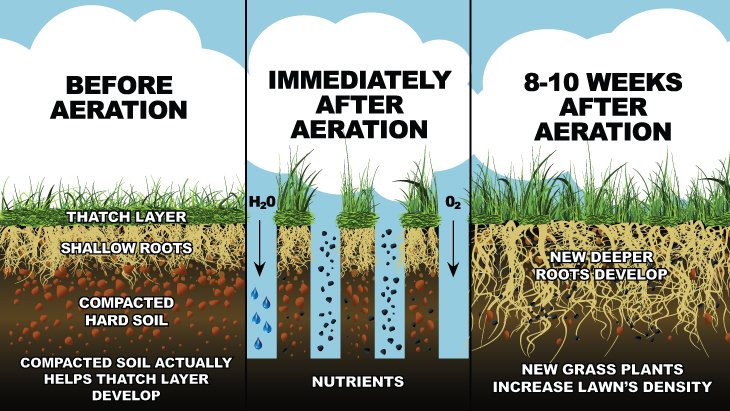

Aeration refers to the process of circulating, mixing, or dissolving air in a liquid or substance. The purpose of aeration is to remove dissolved gases and oxidize metals, such as iron, hydrogen sulfide, and VOCs. This process is essential in drinking water treatment plants and secondary treatment processes of activated sludge treatment in wastewater treatment plants. To achieve effective wastewater treatment, it’s crucial to have an evenly distributed oxygen supply in the aeration system, which helps to promote microbial growth.

The efficiency of aeration depends on the surface contact between air and water, which is mainly controlled by the size of the water drop or air bubble, according to the Missouri Rural Water Association. Aeration brings water and air in close contact by exposing drops or thin sheets of water to the air, or by introducing small bubbles of air that rise through the water. Dissolved gases are then removed from the solution and released into the surrounding air.

Aeration in Wastewater Treatment

Aeration is an essential part of the secondary treatment process in municipal and industrial wastewater treatment. The activated sludge process is the most commonly used method for secondary treatment, according to Oxymem.

Aeration promotes the growth of microbes in wastewater, which feed on organic material, forming flocks that settle out easily. The bacteria in these “activated sludge” flocks are continually recirculated back to the aeration basin, increasing decomposition rates, once they have settled in a separate settling tank.

In industrial applications, water-fall aeration, using spray nozzles, is the most common method of aeration. Another method of aeration is air diffusion, where air is diffused into a receiving vessel containing counter-current flowing water.

Aeration is also used in liquids, soils, and foods to improve quality and reduce contamination. It can be used to oxidize soluble iron and manganese to insoluble precipitates, as well as reduce ammonia and hydrogen sulfide. Aeration is also an effective way to control bacteria.

Types of Aeration

Fine bubble diffusers and coarse bubble diffusers are two common types of aeration systems used in wastewater treatment, according to Environmental Dynamics International.

Fine bubble diffusers are energy-efficient submersible aeration systems that introduce air into water via thousands of fine bubbles. These bubbles promote the transfer of oxygen to water, maximizing air-water contact and are best suited for applications that require maximum oxygen transfer efficiency.

Coarse bubble diffusers, on the other hand, produce larger diameter bubbles to displace, churn, and mix wastewater effectively. They are best suited for conventional aeration, highly loaded systems, sludge storage, aerobic digesters, and channels.

Surface aeration is another type of aeration that is best suited for shallow water applications or when large amounts of oxygen are needed immediately. According to Kasco Marine, splashing-style surface aerators create more surface area for gas exchange, which can add large amounts of oxygen to the water.